Design & Flexibility

GRV valves are manufactured by using advanced machining and engineering techniques.

GRV is equipped with state-of-art computer-aided-design program. The Solid modeling software provides the perfect environment to check components on valve and valve actuator assembly in each design stage.

All 3D models of valve components are calculated by using finite element analysis, proper stress and deflection calculations.

Deflections of each valve component are inspected under extreme loads for ensuring products smooth operation and longer life.

Products

Valve Automation and Remote Control

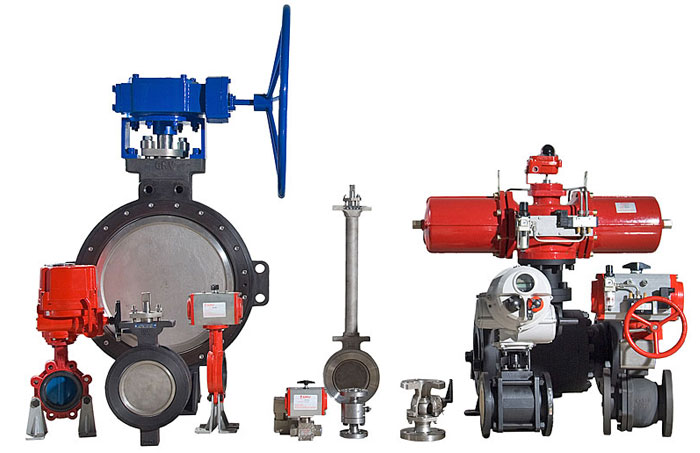

GRV has concentrated its efforts on technology for valve automation and remote control, in order to be able to provide all kinds of actuators and a full range of accessories: limit switches, solenoid valves, position indicators, positioners, speed controllers and smart control packages. Remote communication systems correspond to the modes of Profibus, Modbus and Foundation Field Bus.

All accessories may be assembled and calibrated prior to shipment, including the installation of hardware such as brackets and couplings, stem extensions, three-way crossings, cage kits and replacement yokes.

Quality control

|

|

|

|

GRV valves are manufactured by using advanced machining and engineering techniques.

GRV valves conform to worldwide testing standards, such as ASME, ANSI, API, ASTM, ISO, DIN, EN, BS as well as customers’ special requests. All manufacturing and testing stages, from the raw material selection, through each component production, up to the final valve inspection, are strictly controlled by mechanical and electronic measuring instruments, thereby reducing the chances of human error. Modern high capacity valve test benches at GRV include hydro test, seat leakage test, life cycle test and all kinds of NDT tests, in order to guarantee the high reliability of GRV valves.

Mechanical tests: Tensile test, Hardness survey; Impact test; Bend test

SPECIAL REQUESTS

Qualification

GRV’s Quality Assurance System is certified in accordance with DNV. GRV manufacture has been qualified by a number of products certificates such as , API6D, API607, API6FA, CE, SIL, CCS etc. and can guarantee high reliability of all its products. Meanwhile, GRV has been developing broad collaborations with first-class industrial companies and research institutions, constantly to improve and innovate its products.

Valves and valve actuators for the severe applications

GRV Flow-Controls is an international company with three manufacturing plants in Germany, Italy and China, respectively, producing both manual and automatic types of cast and forged carbon steel and alloy valves in accordance with the international standards (ANSI, ASTM, API, DIN, ISO, BS, JIS & Gost) for applications in the oil & gas, thermal and electric power plants and petrochemical industries. All the GRV products have achieved approvals and certifications issued by many important international industrial companies and associations operating in these fields.

Company profile

The GRV Group is an international company specialized in the manufacture and sale of high performance valves. After nearly 20 years of continuous development, GRV has established his R&D and assembly center in Aachen (Germany), responsible for developing GRV’s products and expanding GRV’s market.

More recently, a new joint venture Company, EMMECI-GRV Flow-Controls, developed in Italy in collaboration with the valve manufacture company EMMECI, provides full services for European markets,while GRV in Chengdu (China) acts as the manufacturing base to provide an efficient service particularly for the Asian markets. Finally, a service center has been opened also in Dubai to meet the request of the markets in the Middle East.

GRV's main products include various types of cryogenic valves, high temperature Y-globe valves, eccentric butterfly valves and so on. Focused on special engineering designs, GRV can provide a wide range of high performance valves to meet the needs of the LNG, petroleum, power and chemical industries.

|

|

|

| GRV Flow-Controls GmbH | GRV Flow-Controls China | GRV Flow-Controls Italy |